AUTOMATIC GLASS BOTTLE WASHER

High Performance Single End Bottle Washer For Sparkling Clean Results

CVH Automatic glass bottle washers are revolutionizing bottling industry by providing automated, high-efficiency cleaning and sanitation for returnable soiled liquor, beer, wine, soft drink, milk and mineral water bottles, replacing manual processes that were time-consuming, risky, and prone to human error.

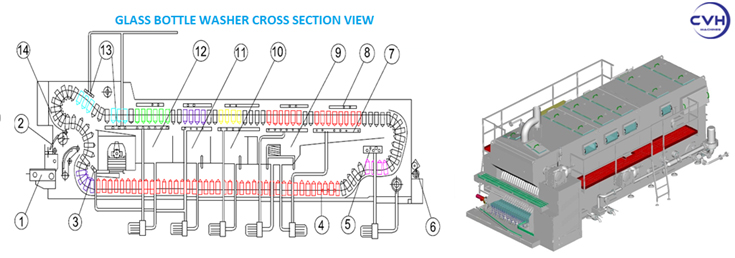

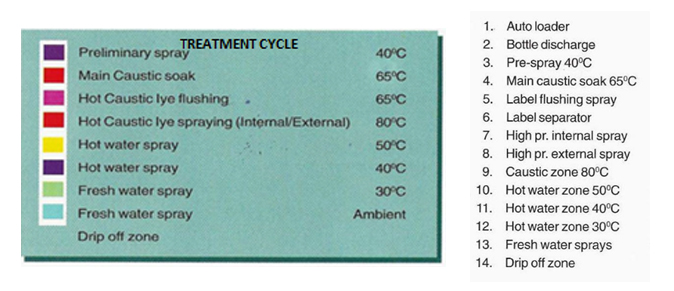

These machines offer comprehensive, multi-stage cleaning cycles, including pre-rinsing, hot caustic soaking and hot water washes, internal and external high-pressure sprays, and final rinsing to ensure bottles are contaminant-free and safe for reuse.

Key technological advancements include label separation, water recycling, and energy regeneration, making the process more productive, cost-effective, hygienic, and eco-friendly.

How CVH Bottle Washers Revolutionize the Industry

- Enhanced Hygiene and Safety: The machines ensure thorough cleaning and sanitation, eliminating residues and contaminants, which is crucial for product quality and safety.

- Increased Productivity: Automatic bottle washers handle high volumes of bottles, significantly increasing output compared to manual washing methods.

- Reduced Risk and Errors: Automation removes the risk of human injury during bottle handling and minimizes errors in the washing process.

- Improved Cost-Effectiveness: By recycling water and energy, these machines minimize steam and water consumption, making the operation more economical.

- Environmental Benefits: Technologies like water recycling and energy regeneration contribute to a eco-friendlier bottling process.

Key Features and Technologies :

- Multi-Stage Cleaning Process: Typically includes a pre-rinse, detergent wash, rinsing with hot water or caustic solution, and a final sanitizing rinse.

- Automated Systems: Automatic loading and unloading of bottles improve efficiency and reduce labor.

- Label and Foil Removal: Specialized systems effectively remove labels and foils, simplifying the cleaning process for returnable bottles.

- High-Pressure Spraying: Internal and external high-pressure sprays ensure thorough cleaning of every bottle’s surface.

- Water and Energy Recycling: Systems are designed to conserve resources by reusing water and regenerating energy from steam and hot water.

Who Benefits :

- Bottling Companies: They gain higher output, hygienic sparkling bottles and more reliable operations.

- Consumers: They benefit from safer and higher-quality products due to improved bottle hygiene.

- Employees: Manual labor is reduced, minimizing risks and creating a safer working environment.

Furthermore, all components are optimally designed to ensure high serviceability and durability. Boasting low heat consumption, low disinfectant carry-over proportion, and economical use of water, our glass bottle washer is able to meet the increasing demands of the beverage industry from both ecological and economic points of view.

Our glass bottle washing machine are widely used in industries such as

- Brewery unit

- Distillery unit

- Dairy plant

- Soft drink plant

- Juice plant

Salient Features :

- Fully automatic bottle washing system

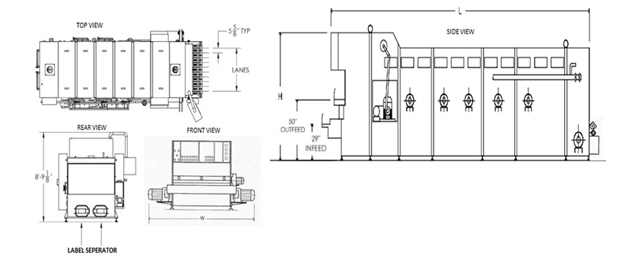

- A wide range of models

- Ecologically friendly solution for bottles reuse

- Universal application in bottling plants

- Outputs from 60-300 BPM

- Efficient cleaning and sterilisation of bottles

- Complete removal of labels and foils

- Label separators

- Digital temperature control

- Steam condensate equipment

- Lye filtration

- Vapour extractor

- Water recirculation

- Low water & steam consumption

- Safety clutches and limit switches

- Dual voltage safety system

- Emergency stop

- Fault annunciator

Function :

During the washing process, the bottles are gradually stripped of dirt. The washing process can be divided into 7 successive phases:

Pre-soak,

– 2-fold pre-wetting

– 1x pre-soaking with water at 35°C

– 1x rinse with water from the overflow of the spray section at 50°C

Long duration soaking, exposure to lye

– main caustic bath temperature 70-85°C

Label removal

– 2-stage label removal

– High Pressure Spray – 1 nozzle per throat.

– Overflow rinse – 2 nozzles per throat.

Spraying and rinsing bottles

– closed section, which prevents leachate from entering other parts of the washer

– 1x splash of 65-70°C water using a fixed shower

– 1x rinse with 65-70°C water using a fixed shower

Spraying, rinsing and cooling of bottles

– 3 sections cascaded

– 6x spraying with water at 20-65°C using rotating showers

– 4x water spraying at a temperature of 20-65°C using fixed showers

– 3 rinses with water at 20-65°C using fixed showers

RO water spray

2x spraying with RO water using rotary showers, (nozzle diameter 2.5 mm)

1x RO water spray with fixed showers, (nozzle diameter 2.5 mm)

Water dripping zone and unloading